Defigo AS (Formerly Ding Dong AS) Overview:

Defigo AS (formerly Ding Dong AS) is a prop-tech company started in 2017 providing an easy to install and use wireless access control systems..

With a focus on easy to use mobile applications, a web based building self-management portal and a sleek physical design Defigo aims to substantially improve building access and management for tenants, managers and owners.

Roles and Responsibilities :

Chief Operating Officer

Director of Special Projects

Quality Assurance and Functional Testing

Joining the team shortly after company founding as the first employee and Chief Operating Officer my responsibilities included marketing materials, sales, project management, buget management, product design and development, logistics/procurement, distribution and more.

I was directly responsible for designing, testing and developing the core product’s mechanical and chassis design, component selection and developing the underpinning manufacturing processes such as injection molding, BOM and supply chain management. This continued from the first concepts through to Generation 2, 3, 4 and 5 as well as the development of the packaging and ancillary products.

As the Director of Special Projects in addition to a number of carry over responsibilities from the COO role I also oversaw the development and introduction of projects, products and functions that the core team did not have the capability or resources to investigate, implement or execute.

Amongst others included a number of sustainability, accessibility and environmental initiatives such as Wooden and Bamboo RFID Keyfobs, sustainable packaging and internal processes for CO2 tracking and mitigation and accessories enabling our products to be used by visually impaired people. Internal company projects included documentation and certification such as ISO 9001, 27001 and 14001.

As the Quality Assurance and Functional Testing role began after identifying a critical need within Defigo for expanded QC and winding down the current Special Projects role.

Within this role I prioritised testing aligned with ITSQB standards, developed processes for software, hardware and documentation testing and development as well as identifying issues with existing practices. Additionally within this role I was involved with service and operational AI intergration and provided critical advice and direction on the implementation, use and consequences of such technology.

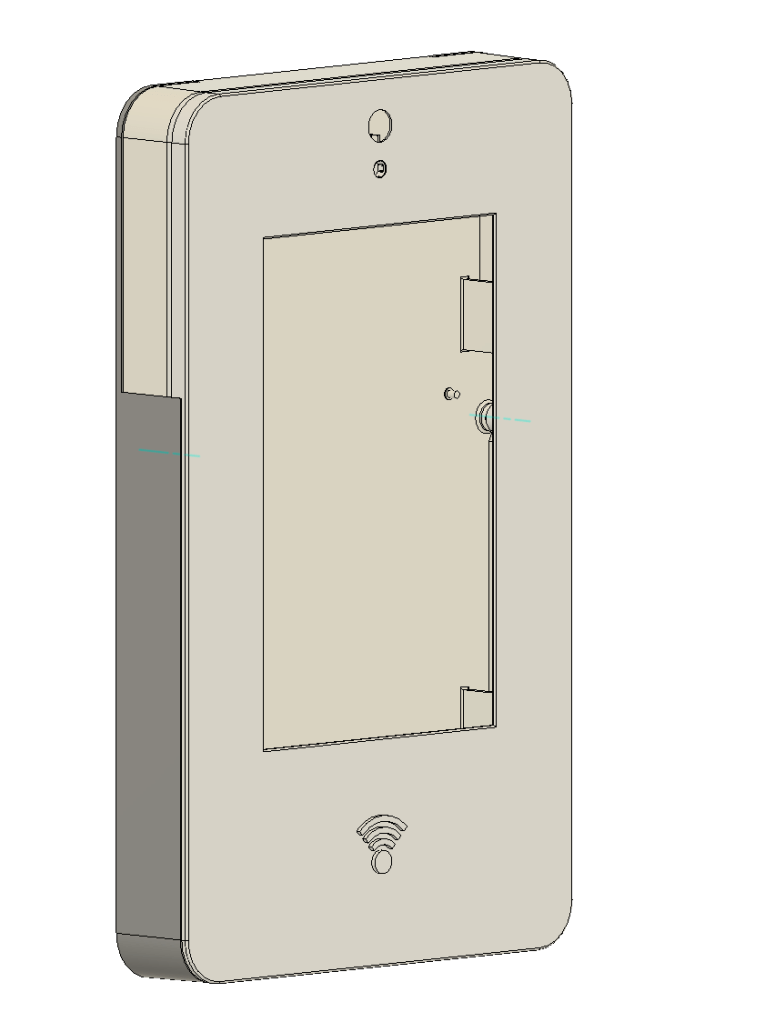

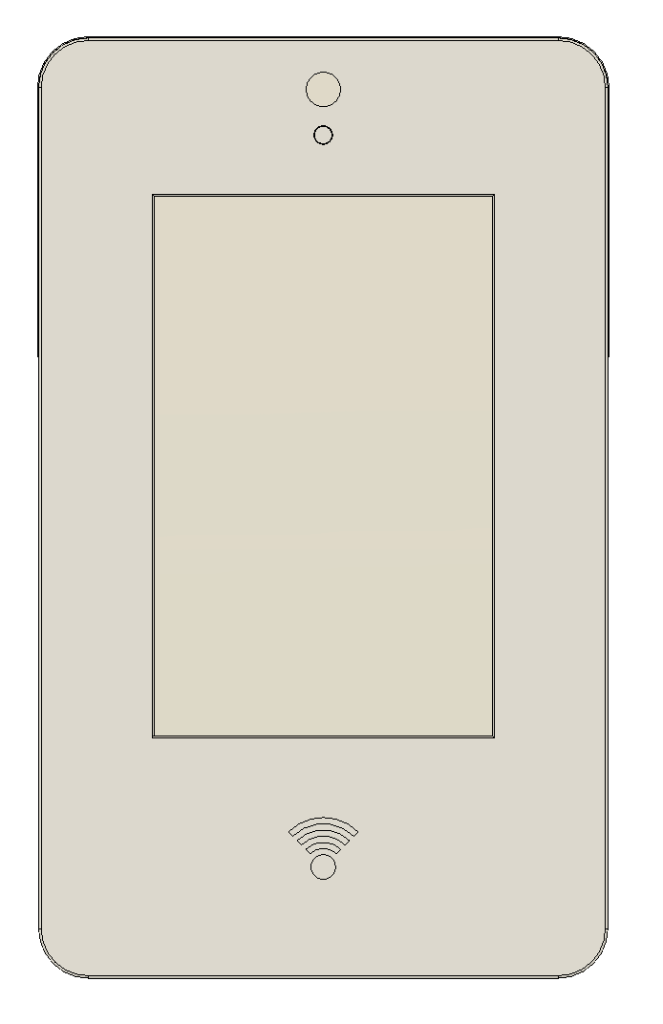

Core Product: Display Box

Generation 5 (Current 5.1):

The current generation of the Display Box features a substantial cost reduction, footprint reduction and feature increase. A full custom front 10.1 display, injection molded design, integrated RFID reader, reduction to a single cable and redesigned mounting system enables quick servicing and installation on both wall and glass surfaces. I also oversaw the thermal redesign process, CE and IP certification and assisted with the FCC certification process.

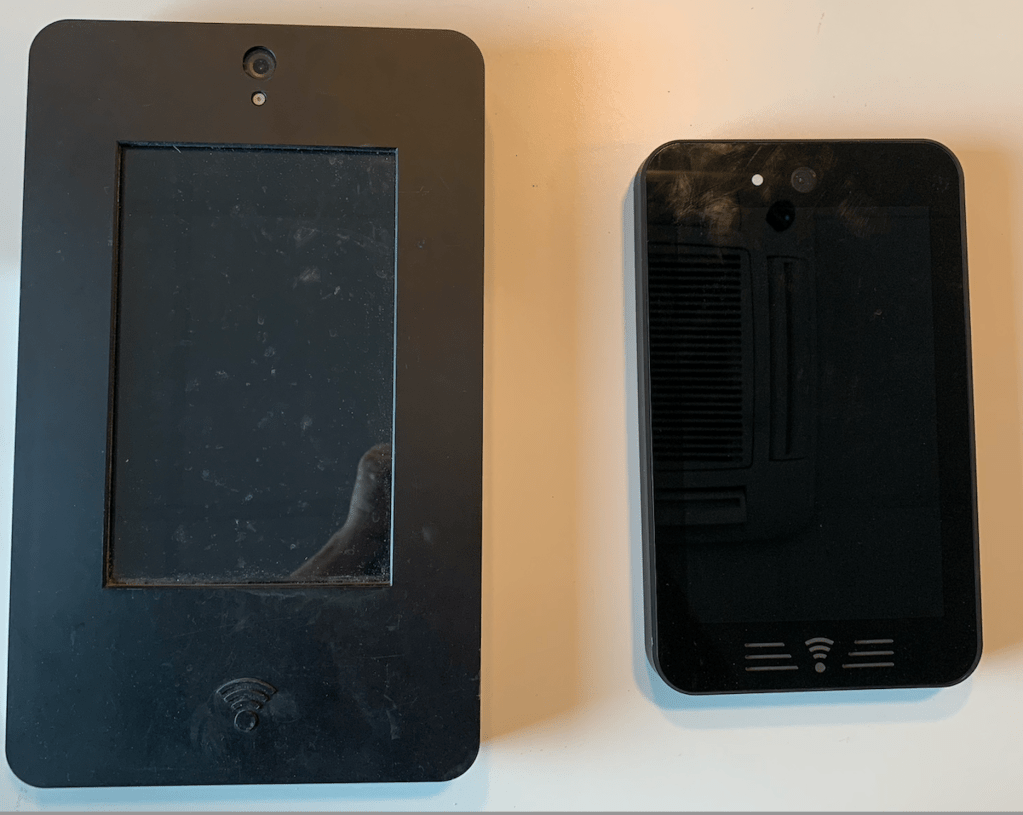

Unit Design Top / Size reduction from Generation 4 Bottom

Generation 4:

The 4th Generation of the display box saw substantial design improvements, including design for injection molding, 10.1 inch display with A/V and RFID capabilities and vertical slide lock functionality. Joined to the Control Unit using a number of cables the display unit was the first scaled production unit delivered. This saw installation in the hundreds both locally and internationally.

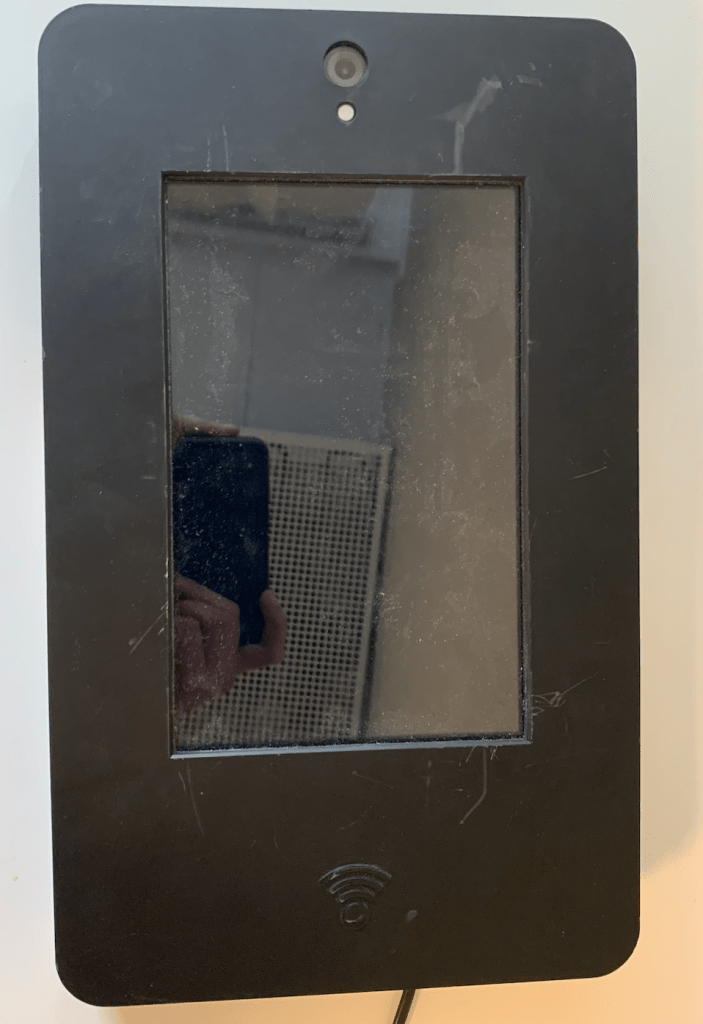

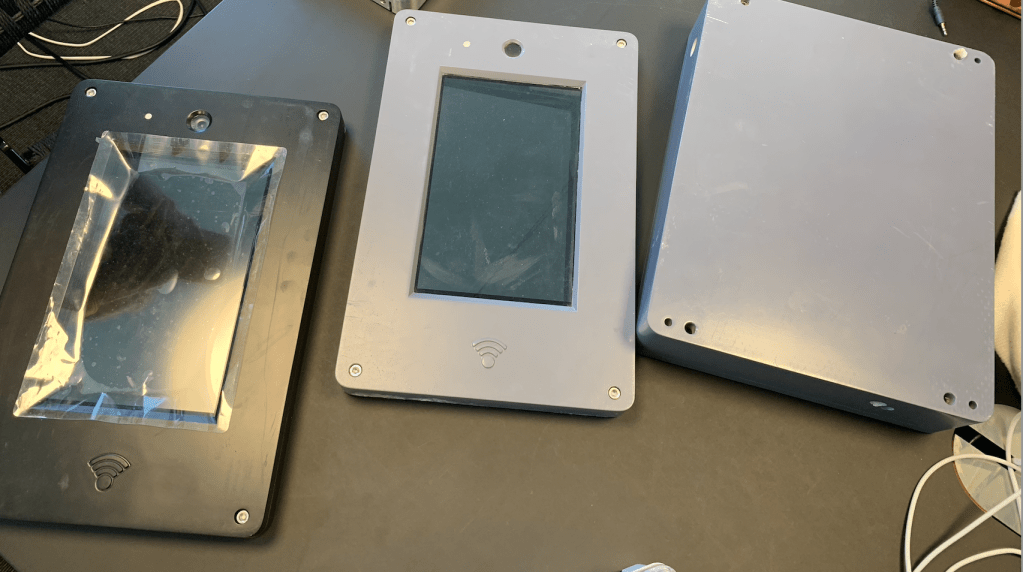

Generation 2 -3 :

Generation 2 and 3 moved from a single unit housing all hardware/software to a split system for security and flexability. The units for this generation were manufactured using a combination of 3D printing and CNC and the customer feedback provided insight into the next generation.

Proof of Concept:

The initial concept was developed as I joined the team, it used off the shelf hardware and components, saw one installation and provided an excellent starting point for myself and the team. From there we made iterative mockups and early use cases to guide development.

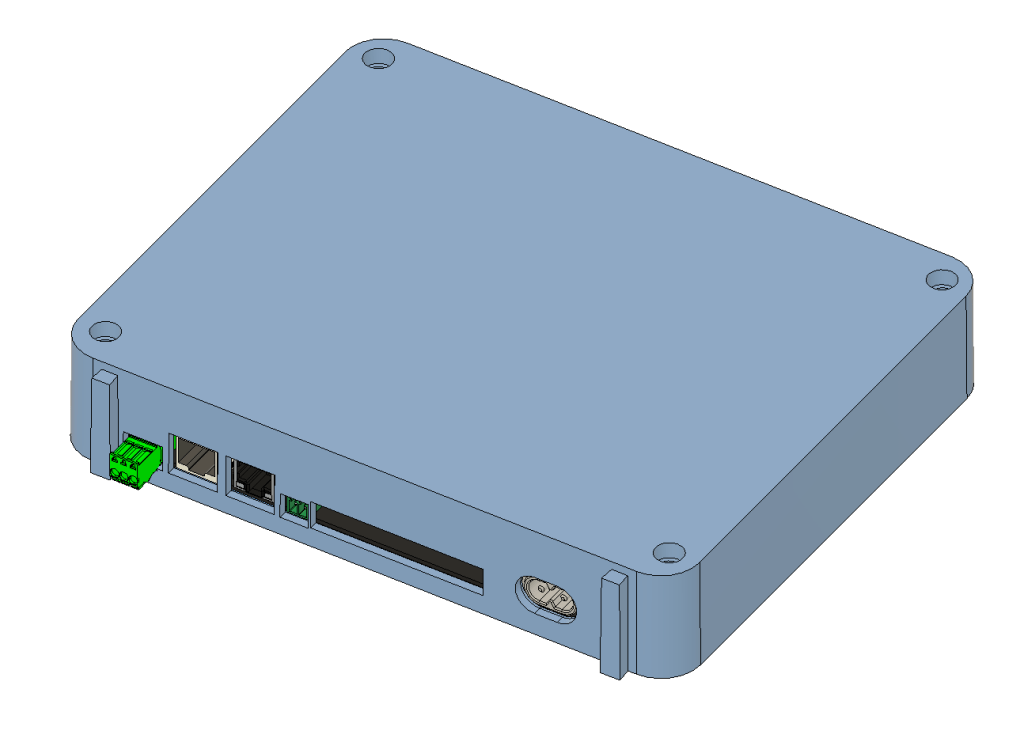

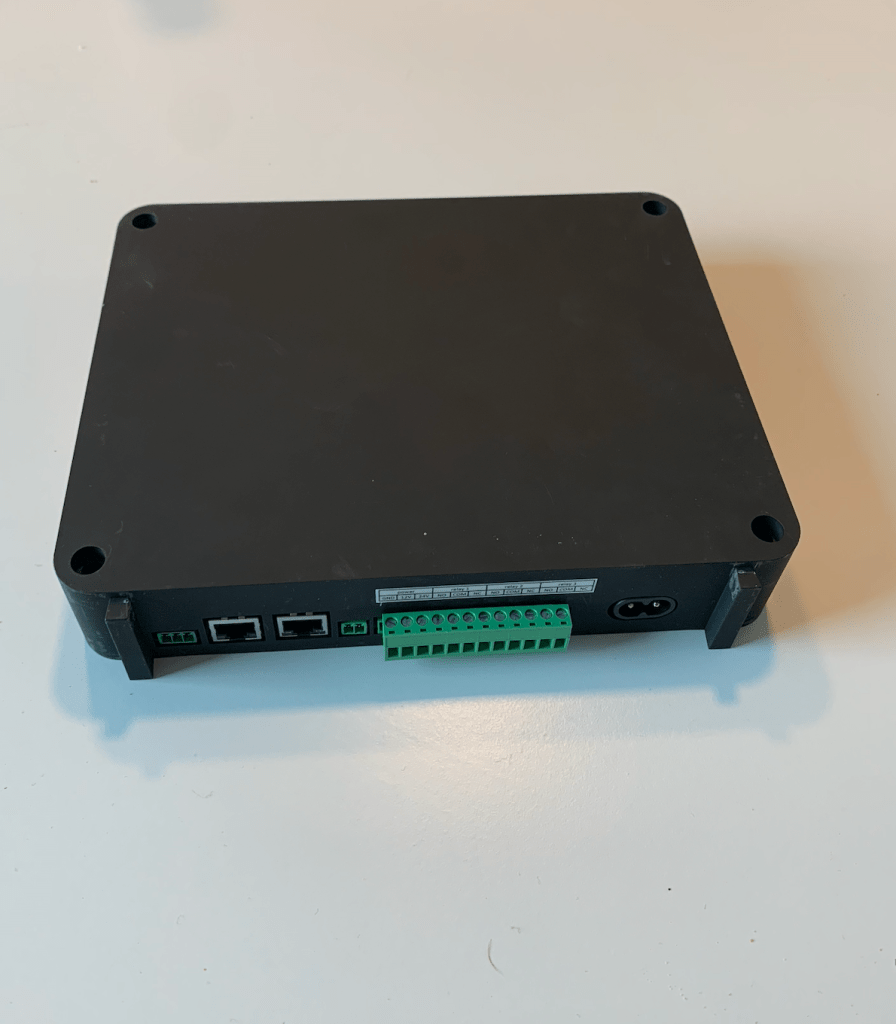

Core Product: Control Box

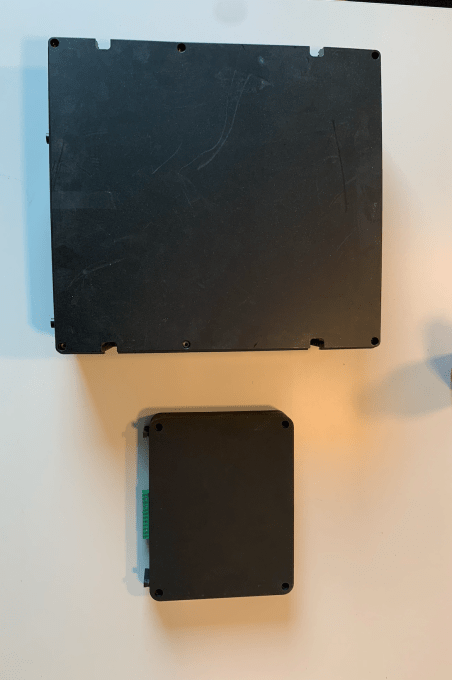

Generation 5 (Current 5.1):

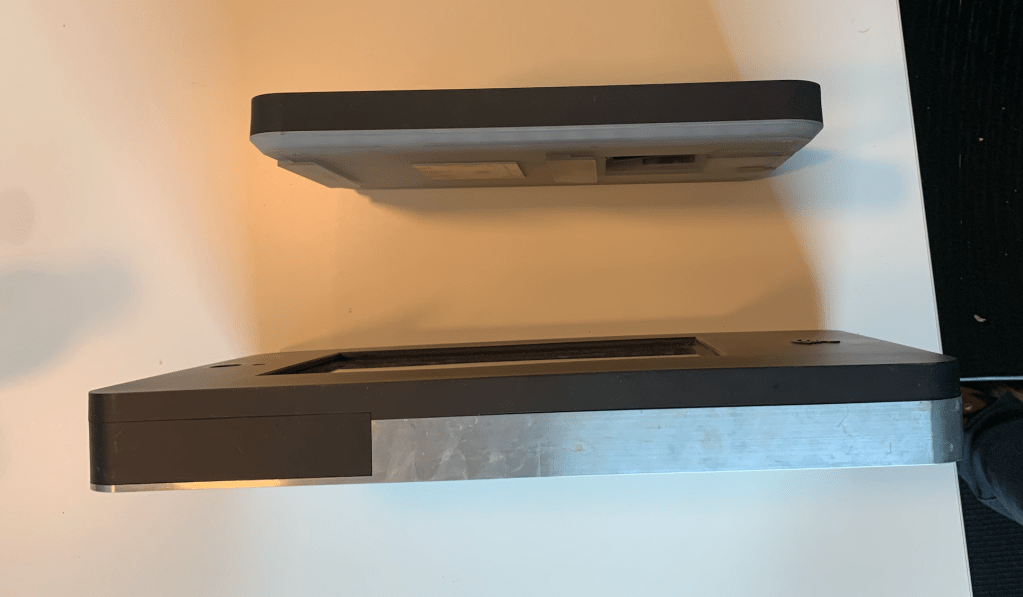

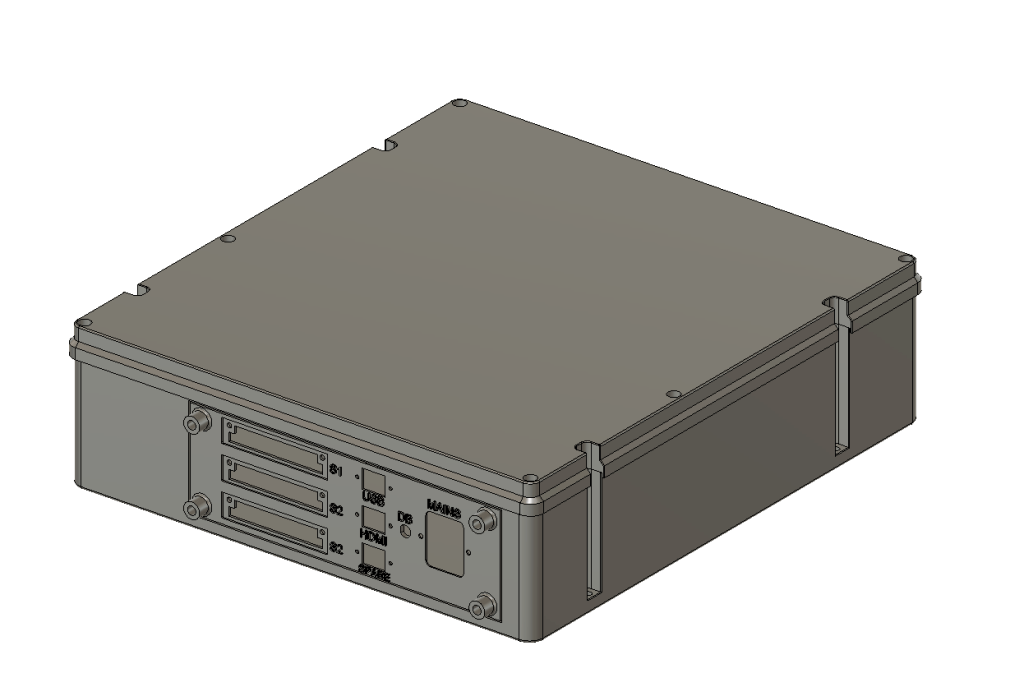

The current generation of the Control Box is easy to install, with external plugs for I/O connectivity and a custom PCB results in a greatly reduced cost and physical footprint over Generation 4. Display Unit connection is reduced to a single cable and can be mounted similar to the Display Unit and had sliding front rails for a cable cover to be attached for increased safety.

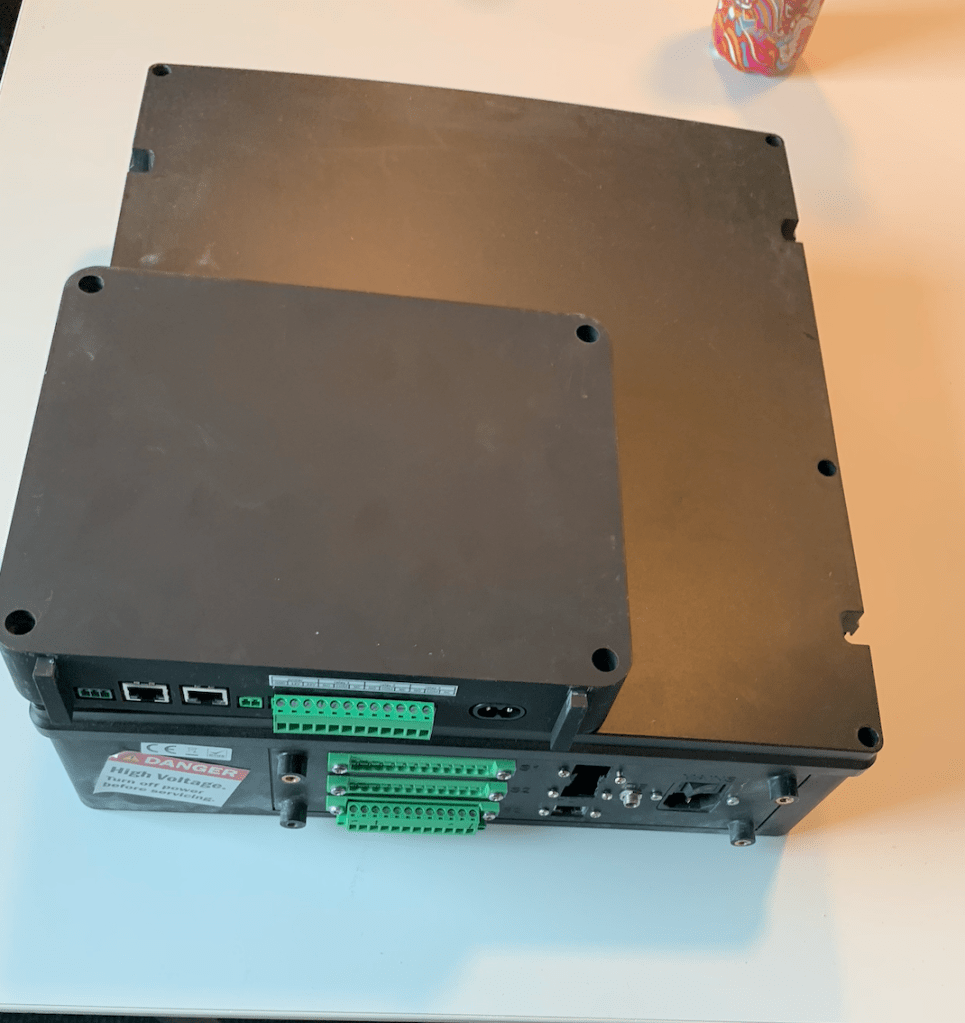

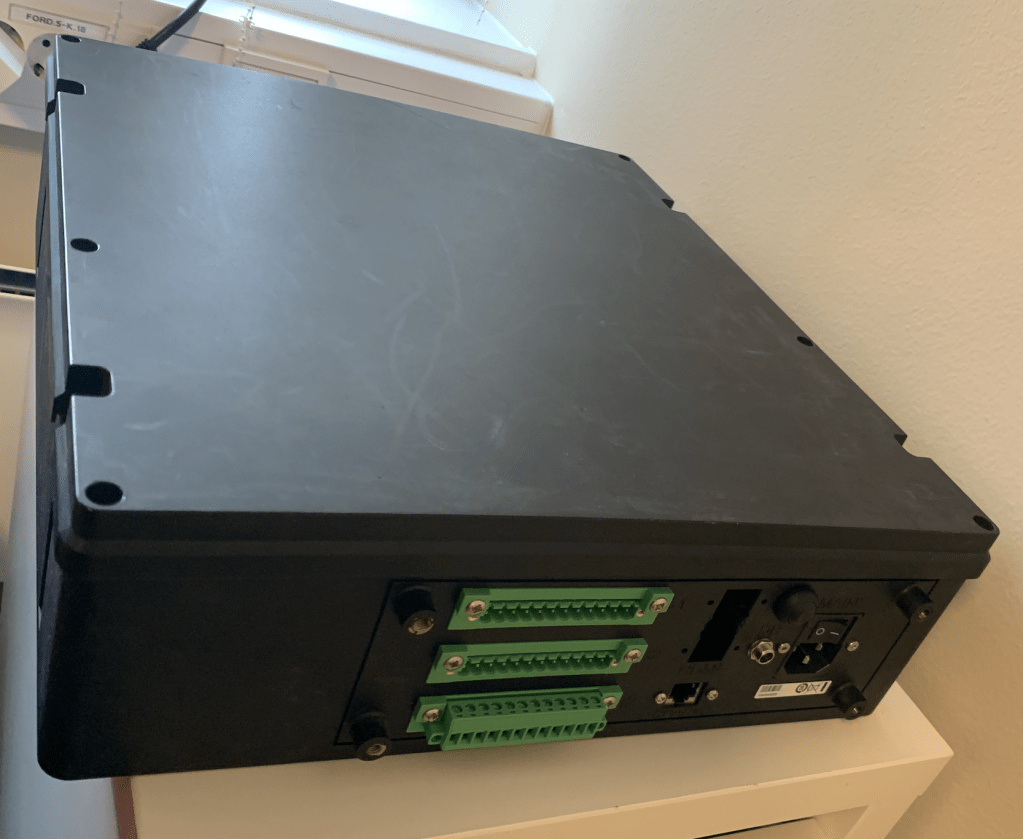

Unit Design Top / Size reduction from Generation 4 Bottom

Generation 4:

The 4th Generation of the Control Box saw the use of injection molded designs, multiple external relays and power configurations. The size reflected the increased hardware and left space for post-production added components.

Generation 2 -3 :

Generation 2 and 3 Control Box was the first to split the hardware, the initial units were 3D printed and manually modified on a case by case basis, Production was limited and acted more as a test platform for future direction.

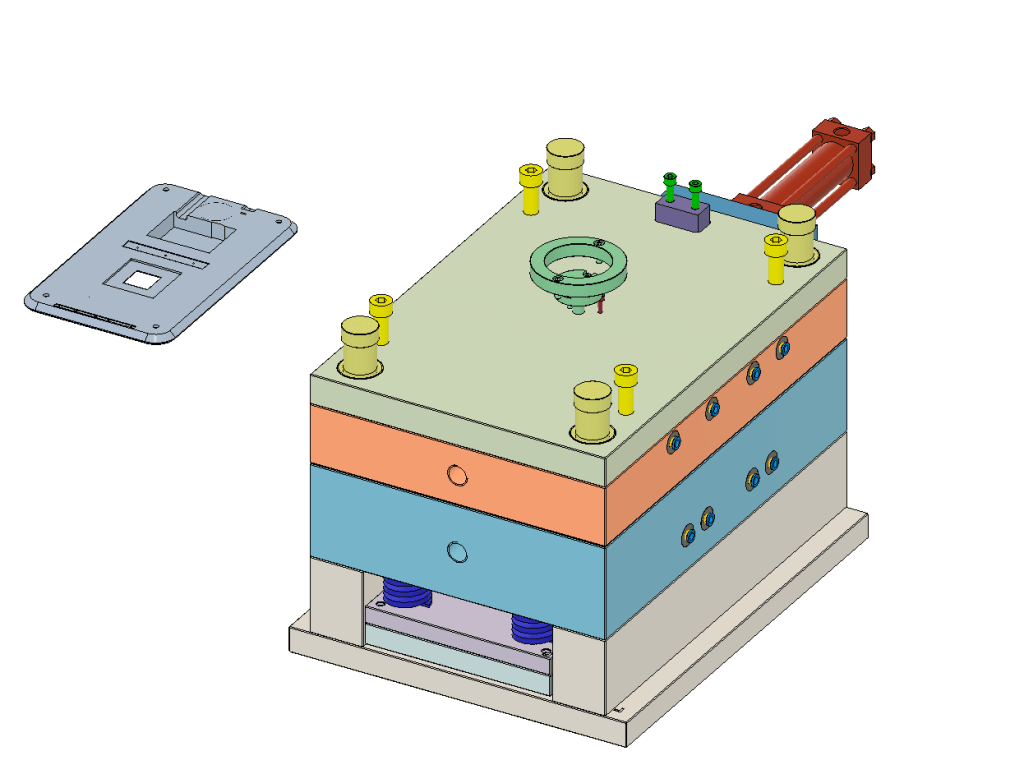

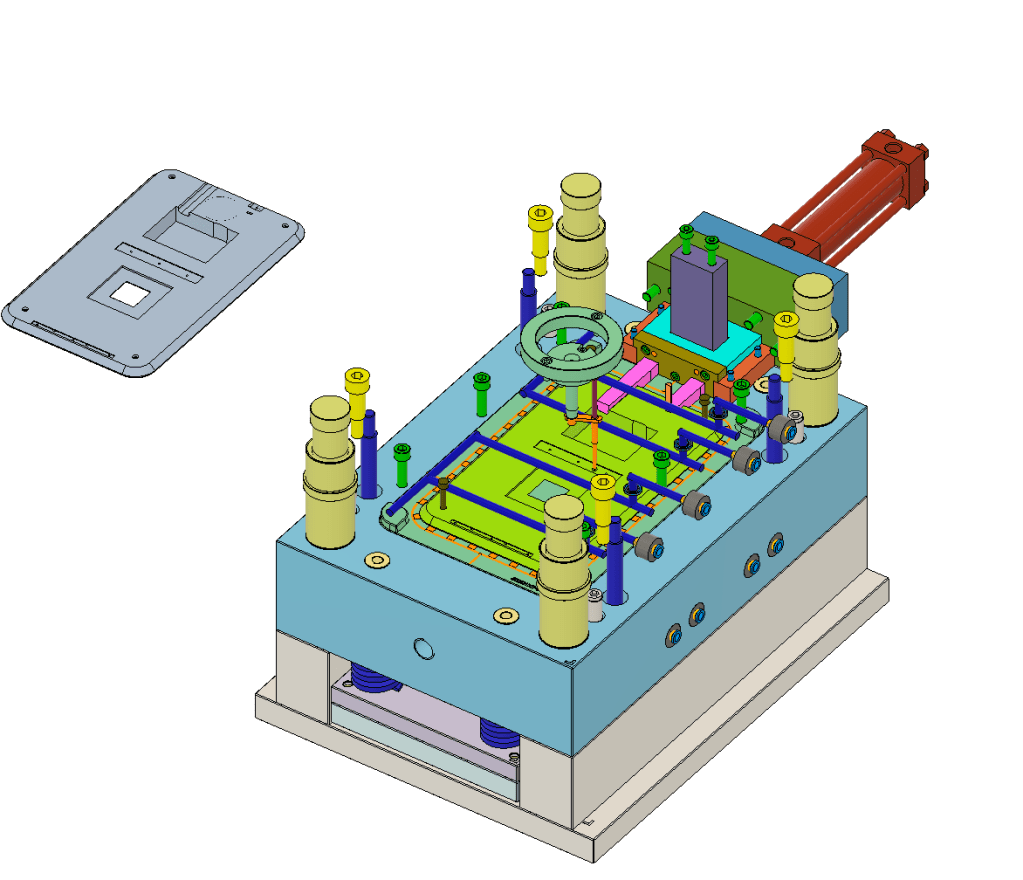

Core Product Manufacturing: Concept to Scale

Additive Manufacting

CNC

Injection Molding

Throughout the product life cycle multiple manufacturing methods have been used depending on the stage and requirments. Initial proof of concepts, asthetics and basic form/function was done using addtive manufacturing: this enabled quick revisions and design changes.

For limited small scale we used CNC methods once the inital concepts are done, this provides a close to finished concept and was usefull for limited small scale production runs. For full scale manufacturing we pivoted to injection molding for all core product chassies, this led to a significant cost reduction as well as mass manufacturing capacity.

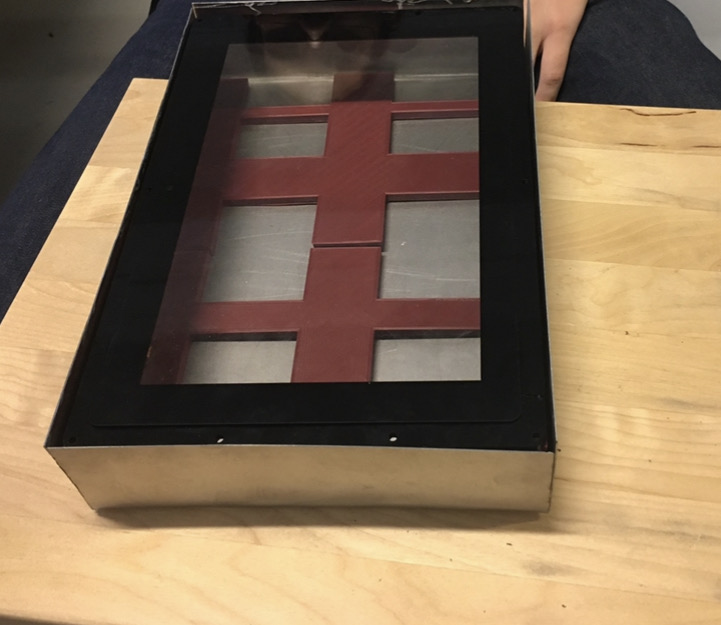

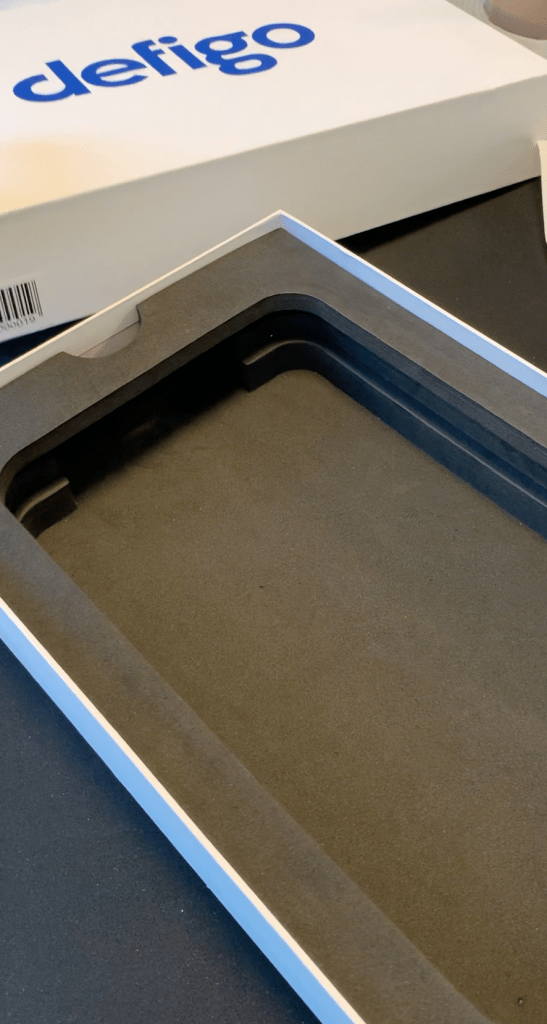

Core Product Packagaing

The core product packaging began as an apple style packaging, with a smooth white semi gloss box with a secure foam insert to hold the products. This was effective and sharp however I was concerned with being unable to properly recycle the units due to the materials, both inside and out.

The second generation involved a full redesign created entirely out of cardboard, with a collapsable cardboard insert and space for accessories. This packaging is entirely recycleable, cost effective and easy to assemble. Taking this as a foundation I pivoted the tablet and RFID Keyfob packaing to match.

Beginning Design:

Post Sustainability Redesign

RFID Keyfob

Accesory/Secondary Products

RFID Keyfobs

InWall Solutions – All Metal, Modular and Service Focused

Haptic Plate for Tablet and Display Box

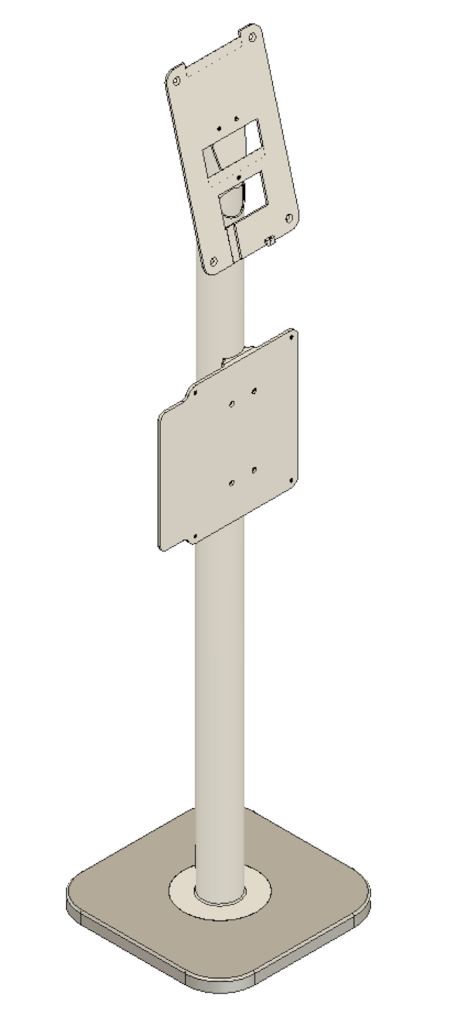

Standing Display Unit

The majority of these products were developed while I was the Director of Special Projects, in addition to and along side the core product development processes. Many of them utilized the same supply chain but in some cases entirely new chains had to be developed by myself from scratch to accomidate the production and delivery while some made it through to manufacturing but did not join the active product line.

RFID Keyfobs:

The mandate initally was to procure standard RFID Keyfobs however due to the incident/loss rate and the fact that the plastic keyfobs are in no way sustainable I privately conducted and funded a development project to transition away from the plastic RFID keyfobs. This resulted in the Wooden series, this presented unique challenges and so I developed the second generation which concluded with the Coconut RFID Keyfob. The Coconut Keyfob met my sustainability targets, as well as being able to provide employment and support to marginalized groups.

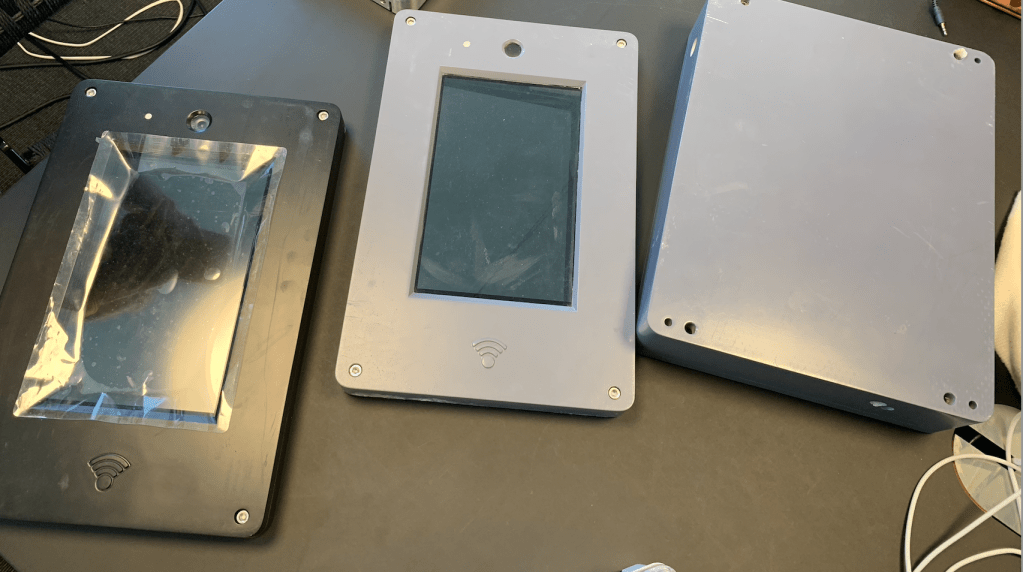

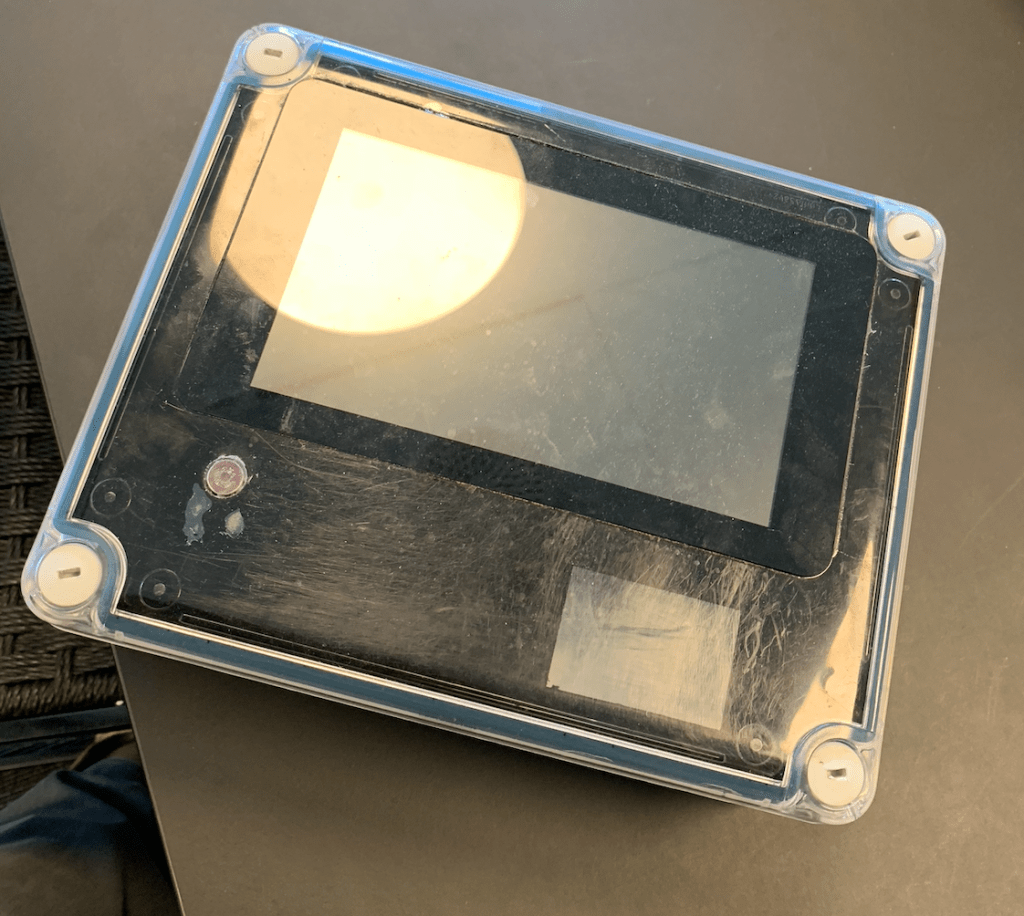

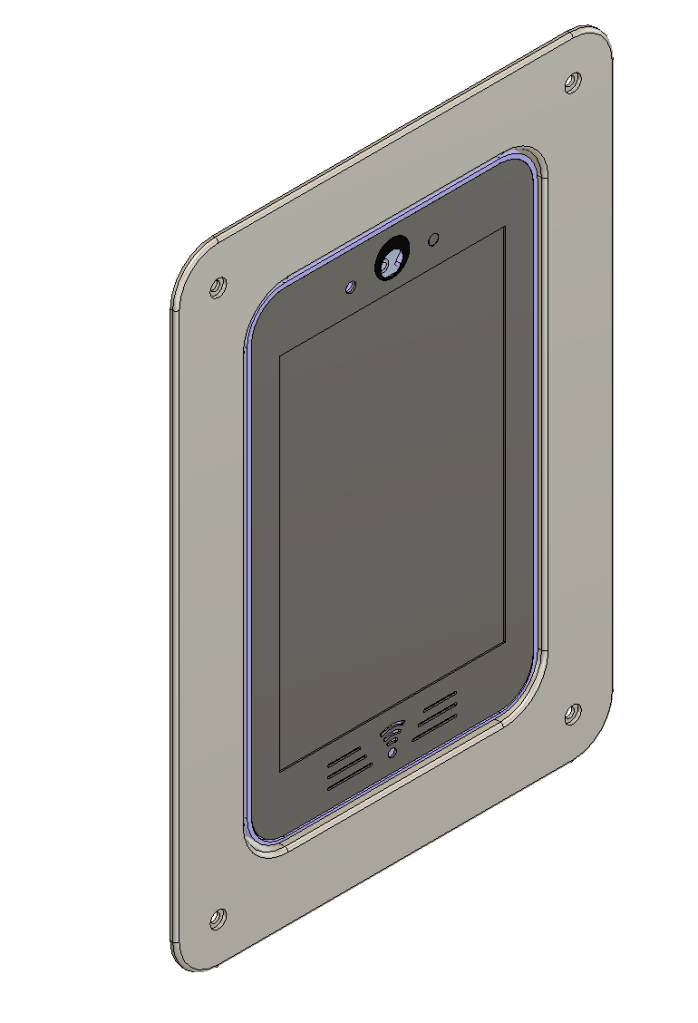

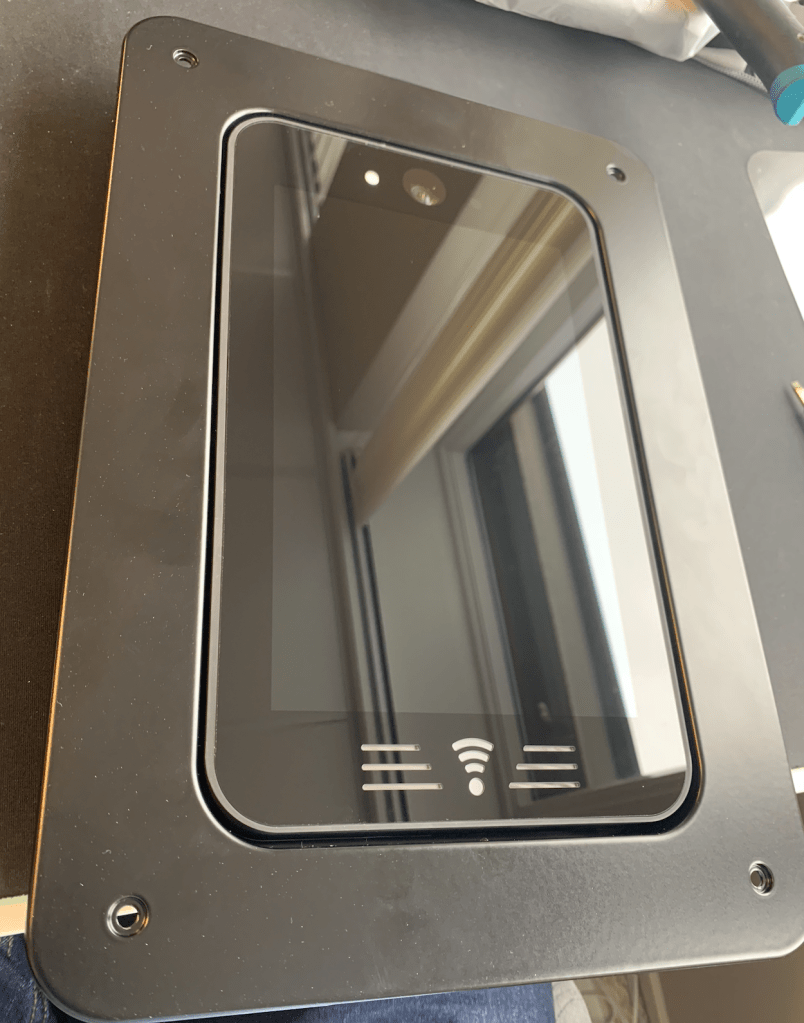

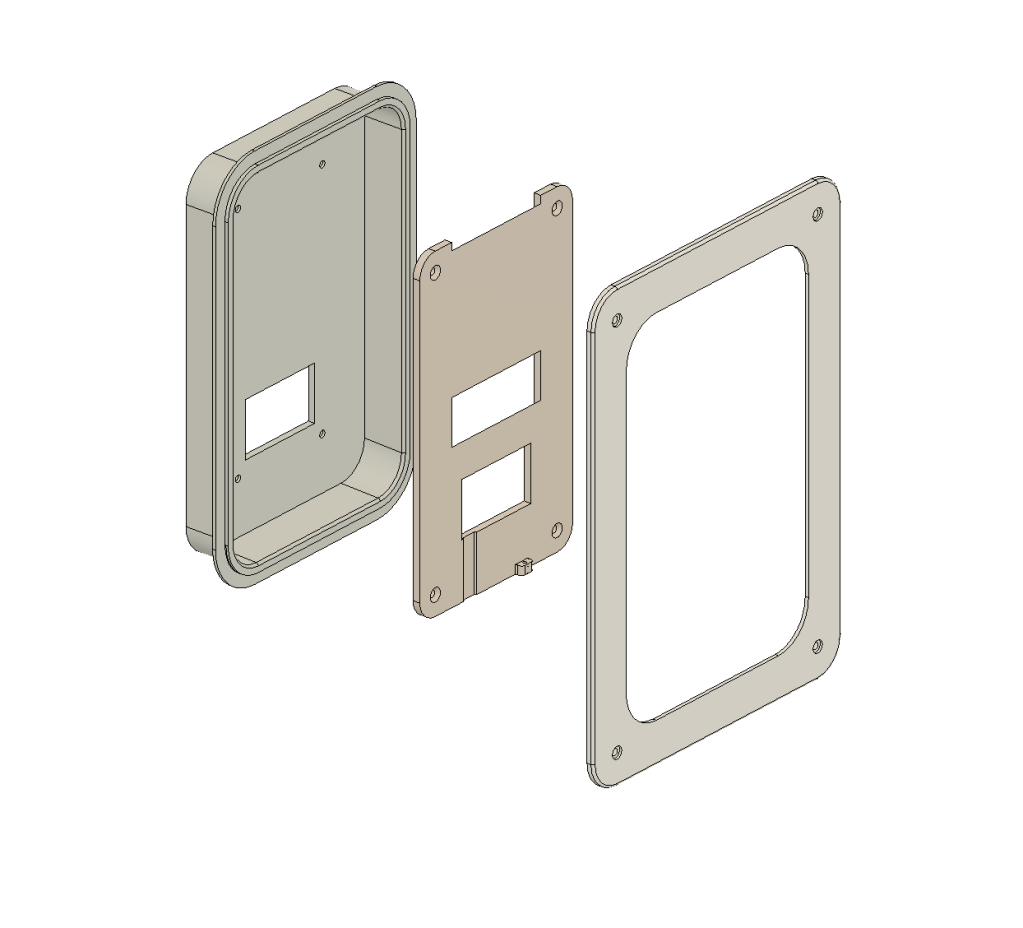

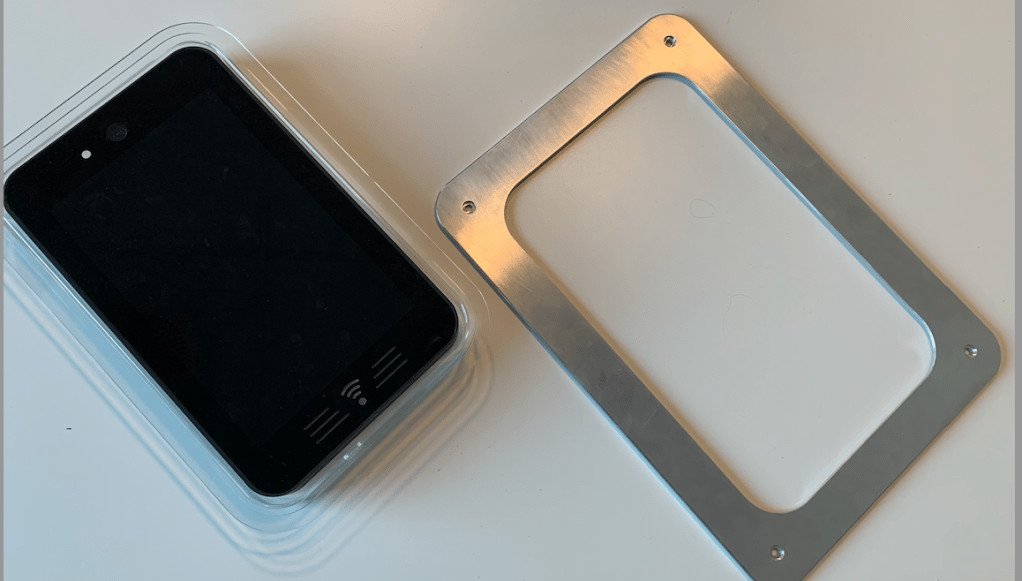

Inwall Solutions:

The primary challenge the core product had was installation choice, the core product can easily be mounted on exterior walls with ease, and with the glass adapter I devleoped the unit can be mounted to glass with ease. The challenge came from new installations that wanted a clean flush installation, this required my to develop a adaptive mounting system without modifying the core product offering.

The inital in-wall concept was an all metal in-wall unit however this had cost, weight and design challenges and didn’t meet the full range of customer reuqirements.

The second generation featured a modular front flange and acrylic housing, this enabled a wide range of installation options due to the drop in design of the core product, as well as flexibility in finishes and meeting custmer requirements. It also reduced manufacturing time, cost and weight due to the acrylic rear housing.

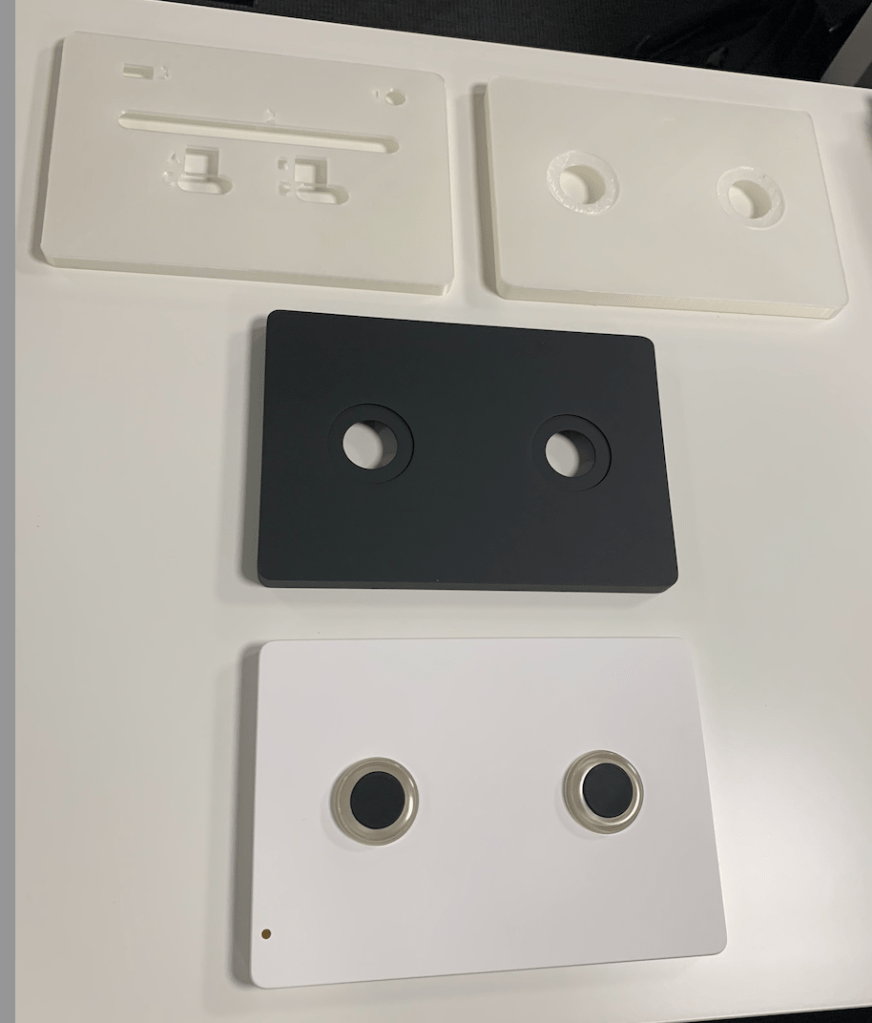

Haptic Plate – Accessibility for Core and Accessory Products

A problem was brought to my attention from the Sales team, they had visually impared users unable to interact with our system, both the core product and the standard in house android tablet and if I could create and demonstrate a solution.

The solution was the Haptic Plate cover, this was an accessory that attached over the top of the android tablet, featured two buttons that interacted with the tablet and the tablet having a simplified cut down UI for the overlay. The product started as a 3D printed mockup with finger space for interaction before moving to proof of concept and finished unit. It features a full screen overlay, simple click on attachement and two custom silicon buttons with large conductive inserts for interation and came in .

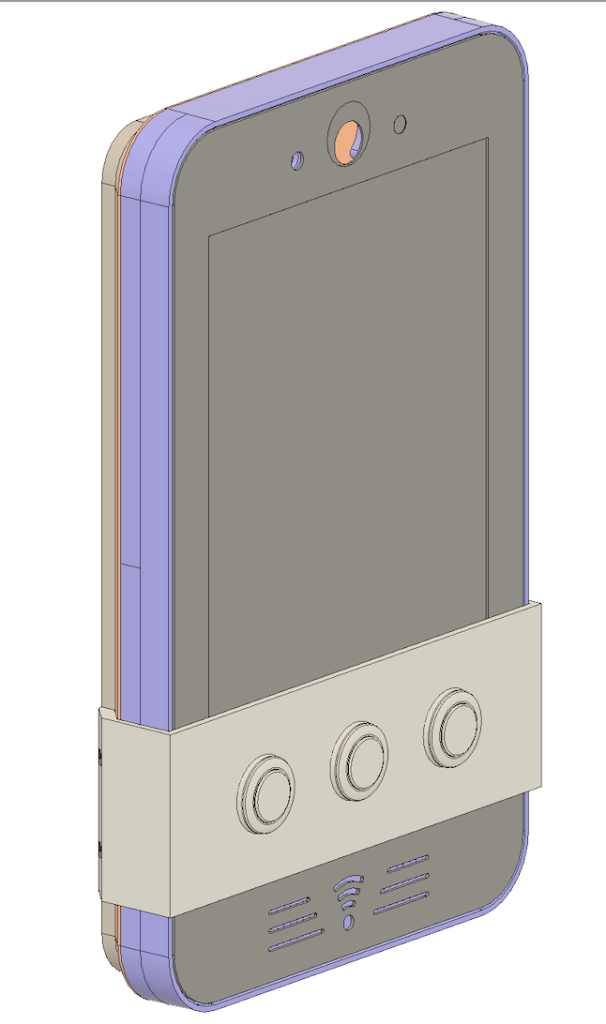

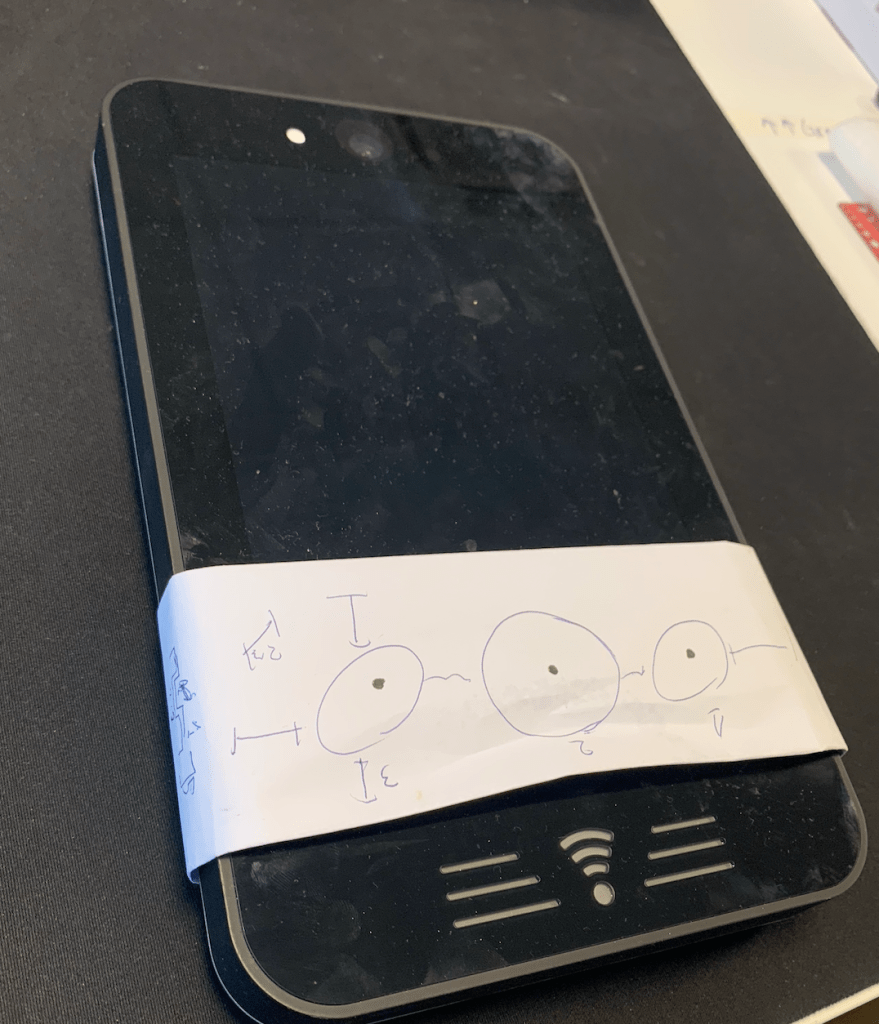

Android Tablet:

The display unit cover operated differntly, it would have three buttons in a band running along the bottom of the display, assisted by voice and an modified UI. Additionally it could be installed onto an existing display unit in the field, enabling easier tennent experience for users.

Standing Display Unit

The standing display unit was designed to be packed down and transportable, easy to assembly and be suitable for enviroments such as exhibitions and showroom floors as well as in person customer demonstrations.